At first look, the practice of insulating flanges seems to have several clear advantages. Insulating the flanges would:

- cut back on radiated heat, thus providing more thermal efficiency (and hence cost reductions) to most thermally intensive industrial processes.

- lower the risk of a worker accidentally coming into contact with the hot, exposed flange.

- provide an initial barrier of protection in the event of a high-temperature steam leak – or other hazardous substance.

While these reasons seem compelling, they miss the central point. The most important function of a gasketed joint is to prevent leakage. When viewed in terms of this primary function, it becomes clear that the negative effects of insulating flanges outweigh the apparent benefits.

- Insulating the flanges boost the temperature of the studs. In the hottest of flange applications, this increases the chance that the studs could thermally yield. Recognizing this fact, Chevron forbids insulating any flanges used in processes above 850-degrees F. They further state that if any flanges at temperatures between 700-degrees and 850-degress are determined to need insulation (for whatever reason), that ASTM A 193 Grade B16 studs must be used, with ASTM A 194 Grade 7 nuts.

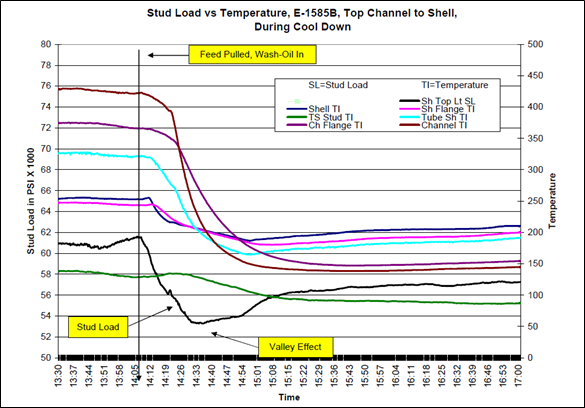

- Insulating the flanges can increase the chance for leakage when a flange is cooled rapidly from the inside (such as when a wash-oil is run through a system). Under these conditions, the bolts cool slower than the flanges, resulting in a measurable (6,000 to 10,000-psi) drop in stud load. This precipitous drop in stud stress is responsible for a high percentage of the leaks that occur with thermal upsets. Even though this is a transient effect, it is only made worse by the use of insulation, which slows the rate at which the bolt can radiate its heat. (Chart on next page, courtesy of Chevron.)

Clearly, the practice of insulating flanges tips the scale in favor of developing more leaks. So as a general rule, flanges should not be insulated.

But what about worker safety?

If the primary purpose of the proposed insulation is personnel protection, that goal can be achieved through other methods that do not impact the thermal balance of the flange. For example, Chevron uses expanded metal guards that prevent accidental contact with the flange, while still allowing free airflow.

Insulating flanges is not only going to make it more likely that you will suffer leaks, but it will also prevent you from noticing those leaks when they first occur – when they can most easily be abated.

Conclusion: It is our position at ERIKS that as a general rule, flanges should not be insulated.