LGG Industrial has been a trusted partner by the world’s largest tire manufacturers for decades. Our customers’ confidence is based on our in-depth industry, product and application knowledge, and the experience of our tenured product specialists who work proactively to avoid downtime and troubleshoot potential problems or hazards.

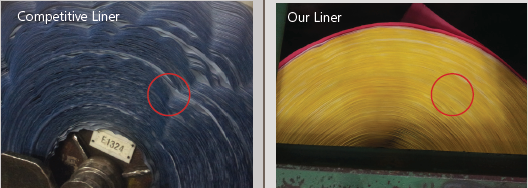

LGG Industrial has committed to invest in the latest technology and equipment to better serve the Tire Industry. Coupled with our proprietary products and vast Industry knowledge, LGG Industrial has become the supplier to many of the largest brands in the Tire Industry. Not only can our Product Specialists help solve problems, at LGG Industrial we are always working on enhancing existing products or developing new products.

Solution Spotlight

By recommending a new splicing technique, LGG Industrial was able to reduce the number of belts used in a year by 24, saving the customer $38,400 annually.

Solution Spotlight

By working 24/7, LGG Industrial was able to save the plant 24 hours of downtime which would have cost $64,800 in lost production.

Take a leap toward industrial excellence and unleash the power of tailored solutions and trusted service. We’re here to help you optimize operating performance and reduce downtime — no matter your industry or the unique challenges you face. Click to find an LGG Industrial location near you.