From virgin PTFE to expanded and modified options, LGG Industrial’s diverse range of PTFE gaskets tackles nearly all chemicals and temperatures (up to 500˚F). We supply PTFE Flange Gaskets for any need, from small batch MRO to high-volume OEM, meeting demanding FDA, USP Class VI, and Chlorine Service standards. Beyond gaskets, explore our versatile PTFE Tapes for diverse sealing solutions.

This 100% pure white PTFE is commonly used in Food & Beverage, Pharmaceutical, and low-pressure / low-temperature applications in the Chemical industry. This PTFE is extremely chemical resistant and FDA-approved. Virgin PTFE is subject to creep (cold flow), and deformations can occur when a load is applied to the gasket.

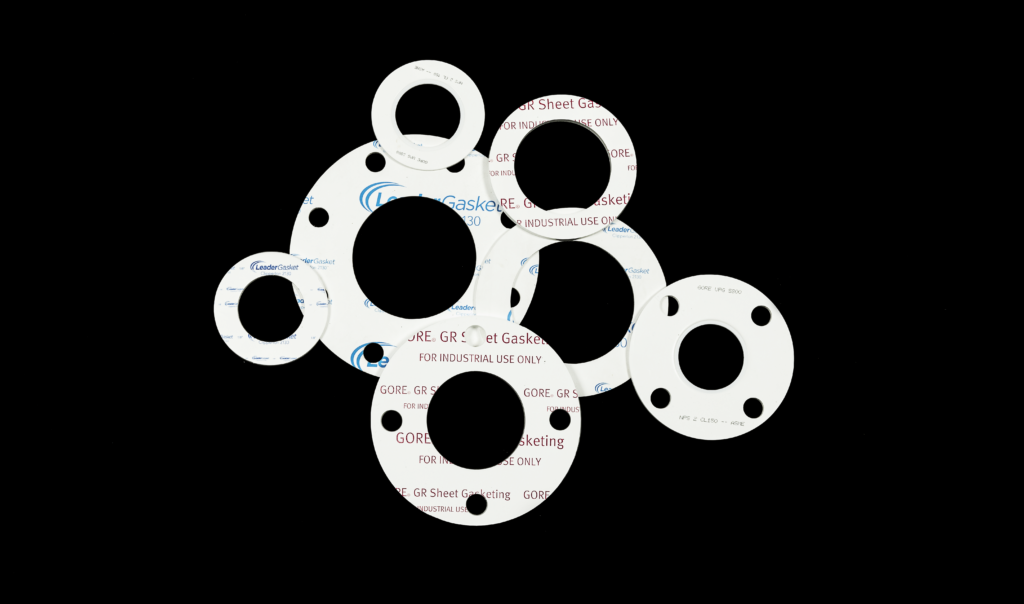

This 100% pure white PTFE is multidirectional expanded (stretched) to eliminate creep (cold flow). This material offers high compression and great adaptability and is exceptionally chemical resistant. FDA-compliant options are available. This material is typically used in steel flanges and is commonly used in the chemical industry. Sheet and cut gaskets offered up to ¼” thickness.

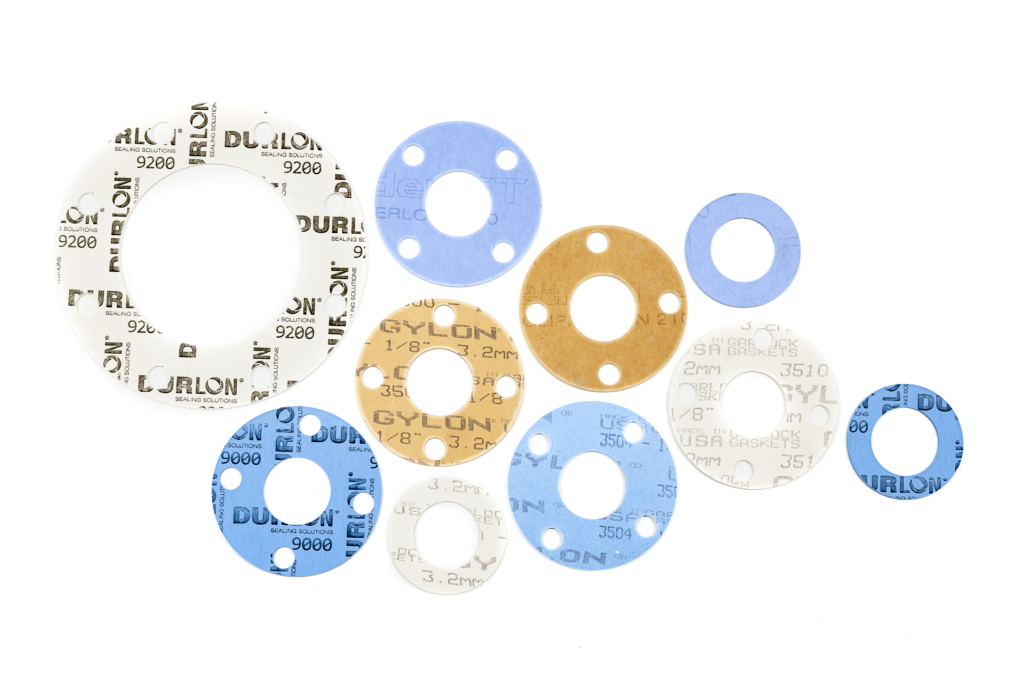

Biaxially calendered Modified PTFE with inorganic fillers is designed to significantly reduce creep (cold flow) and is extremely chemical resistant. These FDA sheets are available with different filler materials (silica, glass microspheres, and barium sulfate). This material can be used in steel, glass, ceramic, and plastic flanges and is commonly used in the chemical and pulp & paper industries. It is typically fawn, blue, or off-white in color.

This 100% pure white Expanded PTFE Gasketing Tape (Monodirectional or Multidirectional) is ideal for quick repair jobs in the field. It is suitable for large, complex, and damaged flanges and comes in various spool sizes and thicknesses. This versatile material can be used in flanges of various materials, including steel. FDA-approved solutions are available.

Take a leap toward industrial excellence and unleash the power of tailored solutions and trusted service. We’re here to help you optimize operating performance and reduce downtime — no matter your industry or the unique challenges you face. Click to find an LGG Industrial location near you.